Our blog

- Home

- Blog

Hellonext is collaborating with Prio / DISA to expand the Spanish group’s network of fast and ultra-fast electric chargers in Portugal and Spain.

Hellonext chargers from the DC range already equip several Prio stations in Portugal and Spain, including the islands. The two companies are reinforcing this strategic commitment to electric mobility as a transition to more sustainable forms of mobility.

The partnership between the Hellonext and Prio / DISA brands will gain even more strength from the second half of this year, when a new production unit for Hellonext chargers is due to open on the Iberian Peninsula.

“We are proud to strengthen our partnership with Prio because it lends credibility to our brand and challenges us to do more and better,” said Manuel Sande e Castro, Hellonext’s Sales Director.

Carlos Ferraz, Director of E-Mobility at Prio, highlighted the solutions provided by Hellonext for the group’s charger network expansion program. “Despite the exponential evolution of recent years, and the work that Prio has been doing since 2010, electric mobility continues to face major challenges, which can only be overcome through strong partnerships such as the one we have found with Hellonext,” said Carlos Ferraz.

This marks another milestone in Hellonext’s international presence in electric mobility.

Hello, Future! Hellonext H2 480 Redefines Electric Vehicle Charging.

As electric vehicles gain prominence, the need for efficient and accessible charging infrastructure becomes paramount.

Our ultra-fast H2 480 EV charger is a game-changing solution! This cutting-edge technology promises to revolutionize the EV charging experience, offering speeds comparable to refueling a combustion engine vehicle.

How the Hellonext H2 480 is leading the way:

- Speedy “Refueling”

With a power capacity of 480 kW, the Hellonext H2 480 boasts ultra-fast charging capabilities, significantly reducing the time required to charge an EV. Imagine the convenience of charging your electric car from 0 to 80 percent in just 10 minutes – yes, the time needed for a quick glance at the day’s news while having a coffee at a service station!

- Cutting-Edge Technology

The H2 480 represents a new era in ultra-fast chargers, equipped with state-of-the-art technology and adhering to the highest safety standards. Offering dynamic power control and the ability to charge up to four vehicles simultaneously, this charger ensures efficiency and convenience for EV owners.

- User-Friendly Interface

The interaction with the H2 480 is intuitive, featuring dual screens and advanced cable cooling systems. With remote software updates and multimedia content management capabilities, the H2 480 ensures a seamless user experience.

- Safety and Reliability

We prioritize safety in every aspect, with the H2 480 adhering to the most rigorous industry standards for impact resistance and protection against debris and moisture.

Additionally, with its robust construction and state-of-the-art cooling systems, our ultra-fast EV charger guarantees reliability even in the most demanding environments.

Here’s how it works:

Offering charging powers between 240 kW and 480 kW, through internal 40 kW modules, the H2 480 allows for the charging of up to four vehicles simultaneously, with dynamic power control in each connector.

Moreover, in terms of energy efficiency, this new equipment sets a benchmark in the market, minimizing energy losses in the vehicle charging process.

The user interaction is intuitive through four screens – a 21.5-inch touch screen and a 7-inch control screen, placed on each of the two sides of the equipment.

The 300A cables feature air cooling (or liquid cooling, in the case of optionally using 500A cables). The H2 480 is compatible with the main types of EV charging standards in Europe: CCS2 and CHAdeMO.

Software updates and equipment status control can be done remotely via Wi-Fi, Ethernet, or 4G, as well as managing multimedia content for advertising.

The safety standards of the H2 480 are among the most rigorous in the sector, receiving IK 10 certifications (impact resistance level) and IP 55 (level of protection against the entry of debris and moisture).

The future is here – let’s enjoy the journey together!

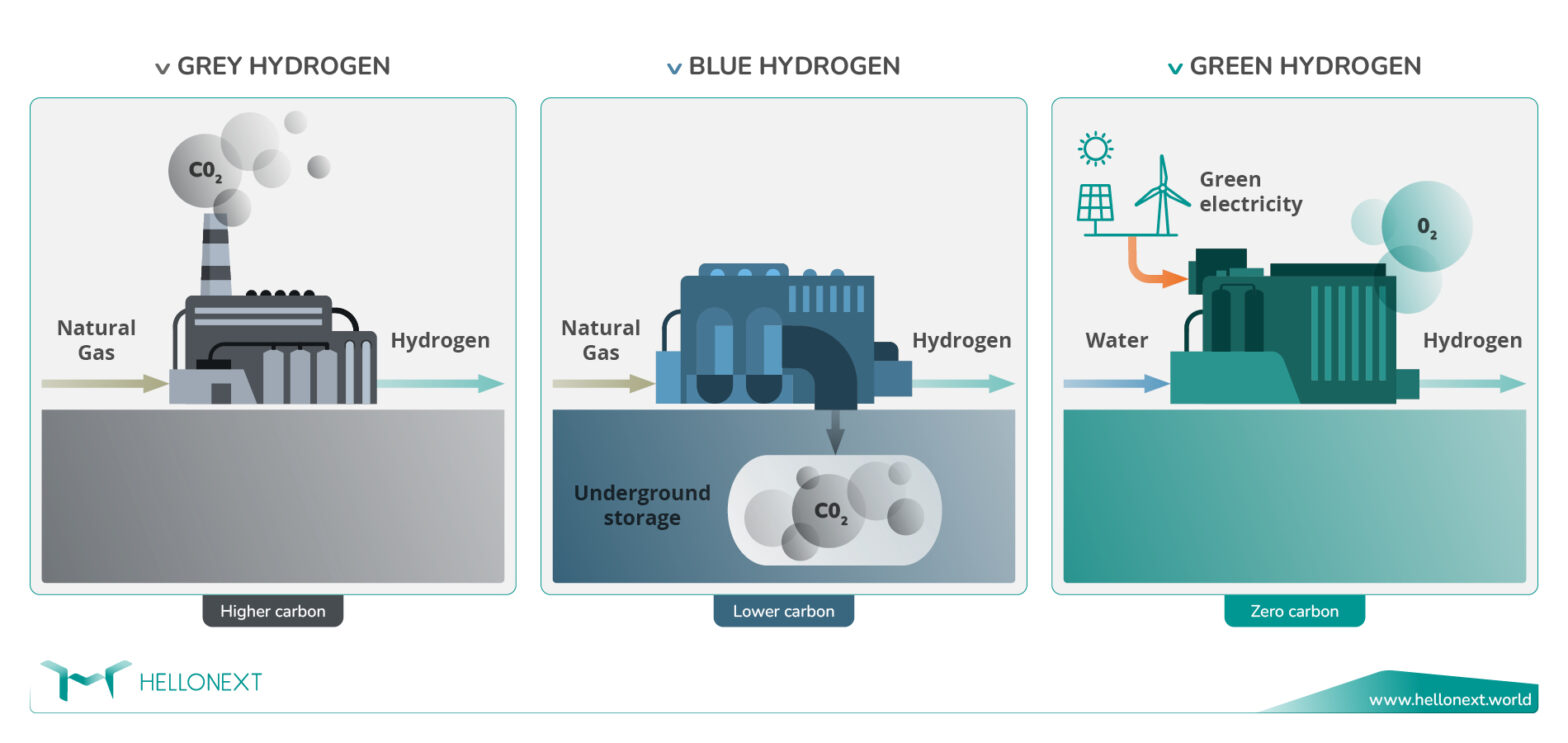

Green, Blue and Grey Hydrogen: the main differences

Hydrogen is often considered the fuel of the future, as it is a clean and versatile energy source that can be used to power everything from cars to factories. However, not all hydrogen is created equal. There are three main types of hydrogen: green, blue, and grey. Each type of hydrogen is produced in a different way and has its own unique characteristics.

Green Hydrogen:

Green hydrogen is produced using renewable energy sources such as wind, solar, and hydro power. This process involves using electrolysis to split water into its two components: hydrogen and oxygen. The resulting hydrogen is clean and emissions-free, making it an excellent choice for powering vehicles and other applications that require a clean energy source.

One of the key benefits of green hydrogen is that it is produced using renewable energy sources, which means that it does not contribute to greenhouse gas emissions. Additionally, green hydrogen has the potential to reduce our reliance on fossil fuels and provide a more sustainable source of energy for the future.

Blue Hydrogen:

Blue hydrogen is produced in a similar way to green hydrogen, but with one key difference. Blue hydrogen is produced using natural gas as the feedstock instead of water. The natural gas is first converted into hydrogen and carbon dioxide through a process called steam methane reforming (SMR). The carbon dioxide is then captured and stored underground, a process known as carbon capture, utilization, and storage (CCUS).

The primary benefit of blue hydrogen is that it can be produced at a lower cost than green hydrogen, as natural gas is a cheaper feedstock than renewable energy sources. Additionally, the use of CCUS technology means that the carbon dioxide produced during the production process is captured and stored, preventing it from being released into the atmosphere. The blue hydrogen emissions range from 1 to 3 kg of CO2 per 1 kg of H2. The problem with this method is when all the stored CO2 is released, as at that point the volumes discharged into the atmosphere will be very high.

Grey Hydrogen

Grey hydrogen is the most common and is produced using fossil fuels such as coal or natural gas without carbon capture and storage technology. This process involves using high-temperature gasification to convert the fossil fuel into hydrogen gas. Grey hydrogen is the most carbon-intensive of the three types of hydrogen, as it produces significant amounts of greenhouse gas emissions during the production process. In the separation of molecules, hydrogen (H2) is captured while carbon dioxide (CO2) is released into the atmosphere. In general, around 10 kg of CO2 is emitted for every 1 kg of H2 produced.

Due to the significant emissions associated with grey hydrogen, it is generally considered to be the least desirable of the three types. However, there are some instances where grey hydrogen may be used as a transitional fuel as we move towards a cleaner energy future.

In conclusion, green, blue, and grey hydrogen each have their own unique characteristics and production processes. While green hydrogen is the most desirable due to its clean and emissions-free production process, blue hydrogen can be produced at a lower cost and with reduced emissions using CCUS technology. Grey hydrogen, on the other hand, produces significant greenhouse gas emissions and is generally considered to be the least desirable of the three types.

Ultimately, the choice of which type of hydrogen to use will depend on a variety of factors including cost, availability, and environmental impact. However, a shift towards green hydrogen production is necessary to reduce our reliance on fossil fuels and combat climate change.

Hellonext’s focus is on the production and implementation of green hydrogen. If you want to learn more about our H2 solutions, reach us at info@hellonext.world.

Image Source: Energy Education

Support for the Production of Hydrogen and Other Renewable Gases

In Portugal, on March 13th, the Ministry of Environment and Climate Action announced the launch of the second phase of the “Support for the Production of Hydrogen and Other Renewable Gases” program, with a budget of €83 million.

Financed through the Environmental Fund, which acts as an intermediate beneficiary of the Recovery and Resilience Plan (RRP), the call for applications is now open for producers of gases from renewable sources (primarily hydrogen and biomethane), exhausting the total budget allocated for this type of investment.

In the first phase of this program, 40 applications were received, of which 25 projects were supported, with contracts already in execution, totaling €102 million. In the second phase of support, the application period runs until July 31st, 2023.

The aim of this call for applications is to support the production of renewable hydrogen and biomethane, with projects that increase the use of biological waste for the production of renewable gases being given higher scores in the final evaluation.

The European Commission also announced that it is preparing the first pilot auctions dedicated entirely to the production of renewable hydrogen. These will be the first financial instruments of the newly announced Hydrogen Bank.

With a budget of €800 million, the European hydrogen auctions will be launched in the autumn of 2023 under the Innovation Fund. In practice, the hydrogen producers who win this tender procedure will receive a subsidy in the form of a fixed premium per kg of hydrogen produced, for a maximum of 10 years of operation.

In Portugal, the government wants to create a centralized system for the purchase and sale of biomethane and green hydrogen, to be determined by the government by June 30th. With the approval of the Energy Services Regulatory Authority (ERSE), the aim is to create a mechanism to support the production of renewable gases or low-carbon gases, with a view to achieving cost parity between biomethane, hydrogen, and natural gas.

To read more about it see the link with all the informations about the announcement: Link Here

Hellonext visit to Spain’s National Hydrogen Center

Recently, our team had an incredible opportunity to visit Spain’s National Hydrogen Center in Puertollano, Spain. This visit allowed us to share our latest developments in the HRS (hydrogen refueling station) project and exchange valuable insights and expertise with some of the leading minds in the field.

The CNH2 is a true center of excellence in the Iberian Peninsula, dedicated to promoting the development and implementation of hydrogen technologies in a wide range of industries.

During our visit, our teams from Hellonext, Petrotec, and Petroassist had the privilege to meet with some of the key figures at the center. This included Beatriz Nieto Calderón, Head of the Applied Engineering Unit, Carlos Merino, Technical Director, and Miguel Ángel Fernández Sánchez, General Manager at CNH2.

Throughout our meeting, we were able to discuss the latest trends and innovations in the field of hydrogen technology, as well as explore potential areas for collaboration and partnership. We were particularly impressed by the center’s commitment to innovation and sustainability, as well as their dedication to providing practical solutions to real-world challenges.

Overall, our visit to Spain’s National Hydrogen Center was an incredible experience that provided us with valuable insights and expertise that will help us to further our work in the HRS project. We would like to extend our sincere thanks to everyone at the center for their warm welcome and for sharing their knowledge and expertise with us.

As we continue to explore the exciting world of hydrogen technology, we look forward to building on this experience and working together to create a cleaner, more sustainable future for all.

Hydrogen – Think Safety First

Hydrogen is a gas with some peculiar characteristics: it is colorless, odorless, and tasteless, so it is very difficult for humans to detect it without the help of gas detectors. Its density in relation to air is approximately 0.08989 kg.m-3, therefore its molecule is the smallest, the fastest, and the one with the lower viscosity.

Hydrogen leaks happen very easily. There are leaks that are only detected with hydrogen and not with other gases, such as nitrogen. When a leak occurs, the escaped gas is concentrated in the highest points of the installation, and this concentration is not uniform. Therefore, the installation must be designed to promote natural ventilation while also ensuring the existence of forced ventilation (exhaust system).

Hydrogen flammability limits are between 4% and 74.5%, meaning that the gas can ignite within this range. The ignition energy of hydrogen is 10 times lower than any other hydrocarbon. For this reason, leakages need to be totally avoided in the installation with the correct sealing of each component and the entire infrastructure.

All the purges must be channelled to the outside, there is the need to evaluate and prevent flammable mixtures with air and to control the atmosphere locally and within the hydrogen range of action. Local ventilation, security signs, and the exclusion of fire sources, including the safety information prohibiting smoking in the area, are extremely important. Note that when in flame, hydrogen is also difficult to visualize since the flame is not visible to the naked eye, and it does not pollute the air when burning.

An important note regarding hydrogen compatibility with other materials, particularly ferrous alloys, and titanium: hydrogen weakens this type of material, so they should not be used together.

For safety reasons, the entire installation (equipment, piping, storage, etc.) must be connected to a grounding system and monitored to confirm the installation’s water tightness. Whenever there is a need for an intervention, the installation must be inert with gaseous nitrogen (or another neutral gas such as helium or argon).

All the material and equipment used in the installation must be compatible with hydrogen, due to the embrittlement phenomena of low-carbon structural steel.

For Hellonext, safety is extremely important, and keeping people secure is our main priority. We understand that with the contribution of all the people involved, all accidents may and must be avoided. More than believing that all accidents can be prevented, we understand that developing a safety and security culture in all our projects is an essential condition for operating not only hydrogen but also electric charging.

To know more about Green Hydrogen, you can contact us here. We will be happy to answer your questions and know more about your business challenges.

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |